Rock Mechanics Laboratory

Description

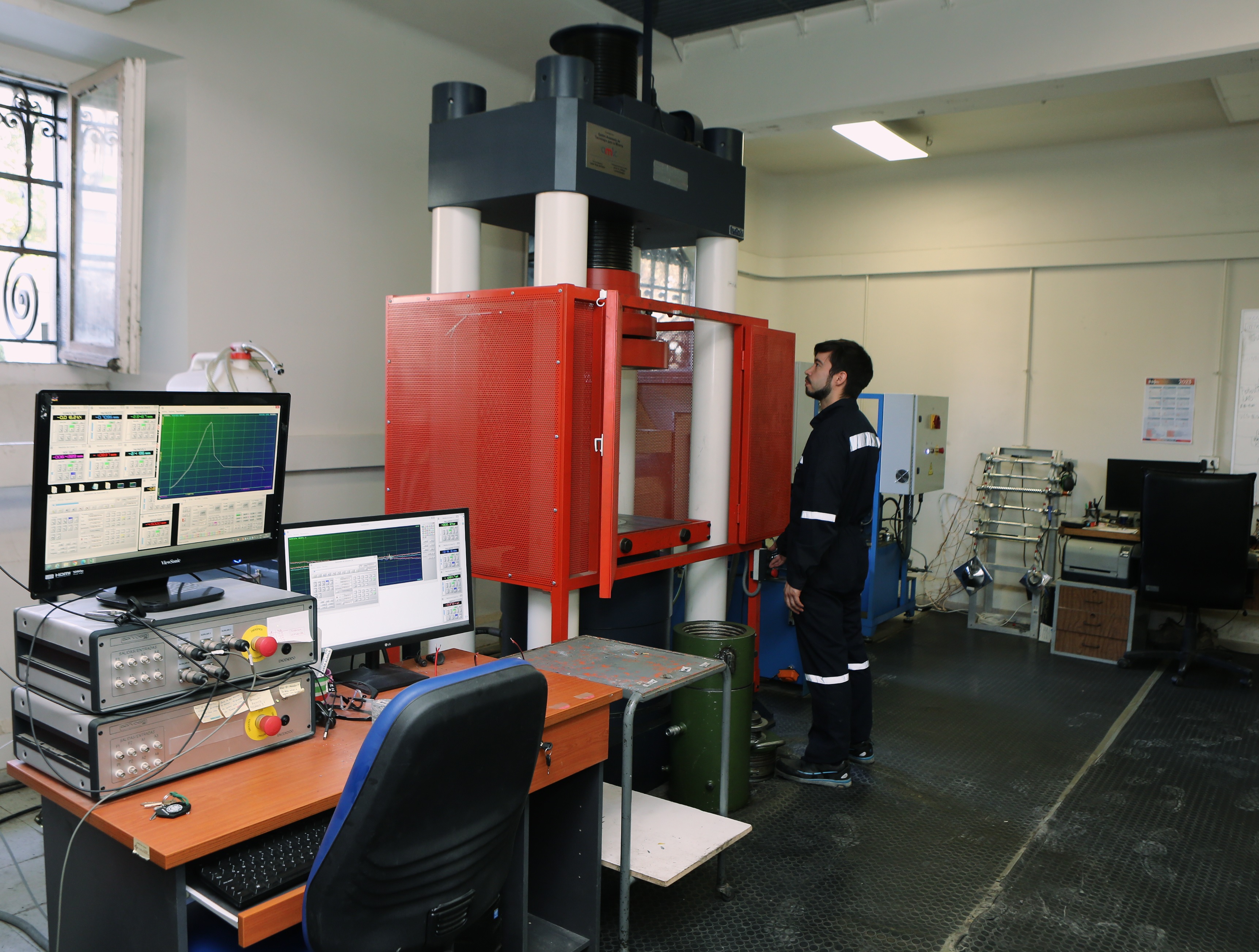

This laboratory's main purpose is to contribute to research and teaching in the areas of geomechanics and mining design. It is located in the underground of the Mining Engineering Building at the Faculty of Physical and Mathematical Sciences of the University of Chile, with an area of 100 m2.

Its professionals have expertise in intact rock characterization, estimation of rock mass properties, design and stability of underground and surface excavations, excavation support, mining-induced seismicity, and blasting. This knowledge is complemented by technology and the development of computational tools, which positions the laboratory at a national and international level.

We offer multiple solutions to the mining industry for the characterization of rock masses through destructive and non-destructive testing. Additionally, we have licenses for specialized software in the area, including Itasca (FLAC3D, 3DEC, PFC3D), Rocscience (RS3, RS2, Slide, DIPS, among others), and Simulia (ABAQUS).

Destructive Test

Unconfined Compressive Strength (UCS)

This test allows for the determination of the unconfined compressive strength (UCS) of rock in the laboratory, or its resistance to simple compression. It is a test used for rock classification based on its strength. Standard ASTM D7012-10, ISRM (1981), ISRM (1979b), ISRM (1999) are used for this test

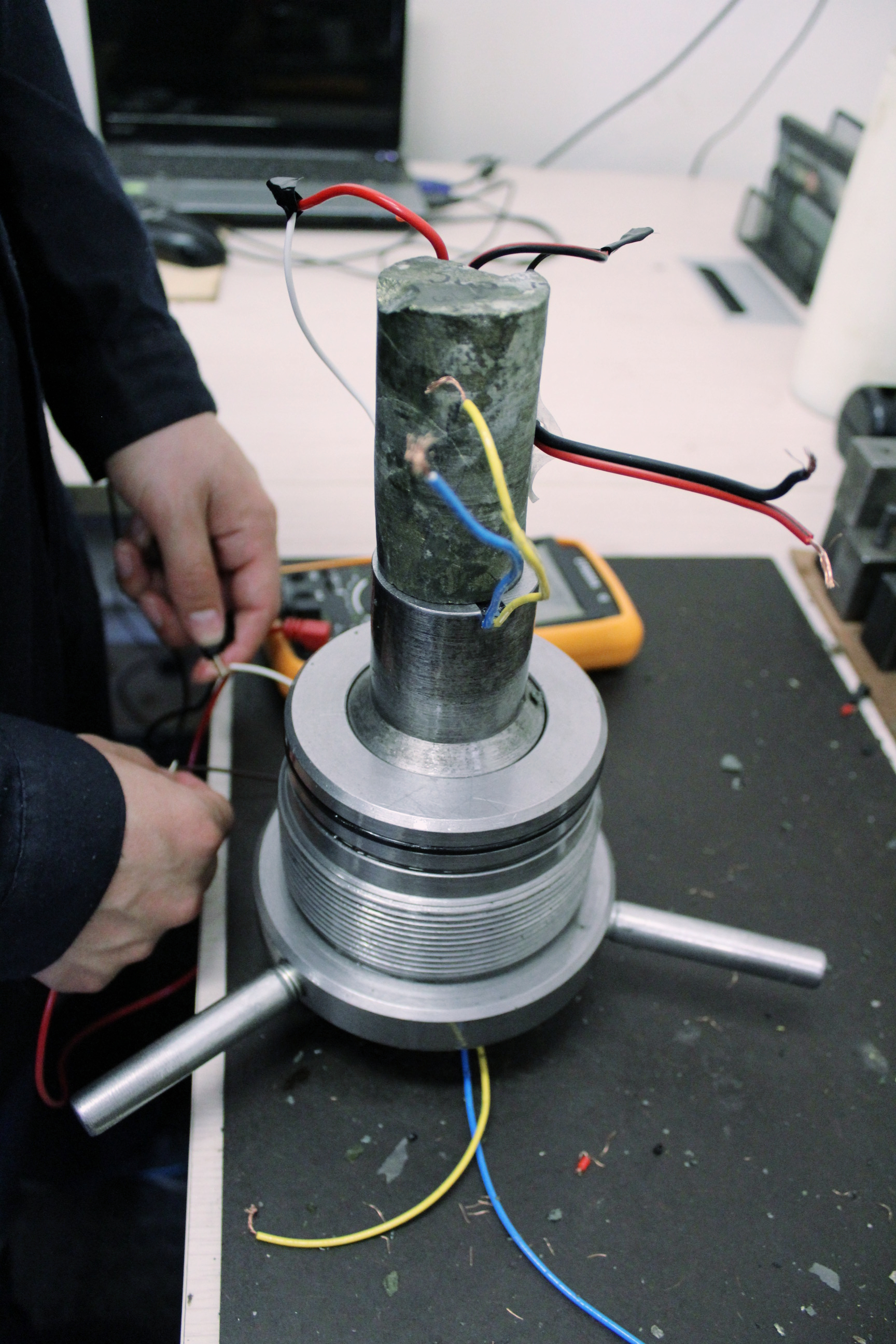

Triaxial compressive test

This test represents the conditions of rocks in situ subjected to confining stresses by applying uniform hydraulic pressure around the specimen. It allows for the determination of the strength envelope of the tested rock material, from which the values of its resistance parameters, cohesion (c) and friction angle (phi), can be obtained. Standard ASTM D7012-10, ISRM (1981), ISRM (1978d), ISRM (1983) are used for this test.

Point Load Strength Index (PLT)

The point load test (PLT) is used to determine the uniaxial compressive strength of irregular rock fragments, cylindrical core samples, or blocks based on the point load strength index (Is) and their anisotropic strength index (la). Standard ASTM D5731-08 and ISRM (1985) are used for this test.

Direct shear test

The direct shear test is a procedure performed to define the strength properties of materials under the effect of combined loads, where the shear force is generated along a specified horizontal surface. Standard ASTM D5607-08 and ISRM (1981) are used for this test.)

Tensile strength test: Indirect (Brazilian test)

This test allows for the determination of the tensile strength of cylindrical rock specimens. Standard D3967-08, ISRM (1981), ISRM (1978b) are used for this test.

Sample preparation

In the sample preparation room, cylindrical specimens from rock outcrops or drill cores are cut and ground. Standard ASTM D4553-08 and ISRM (1981) are used for this process.

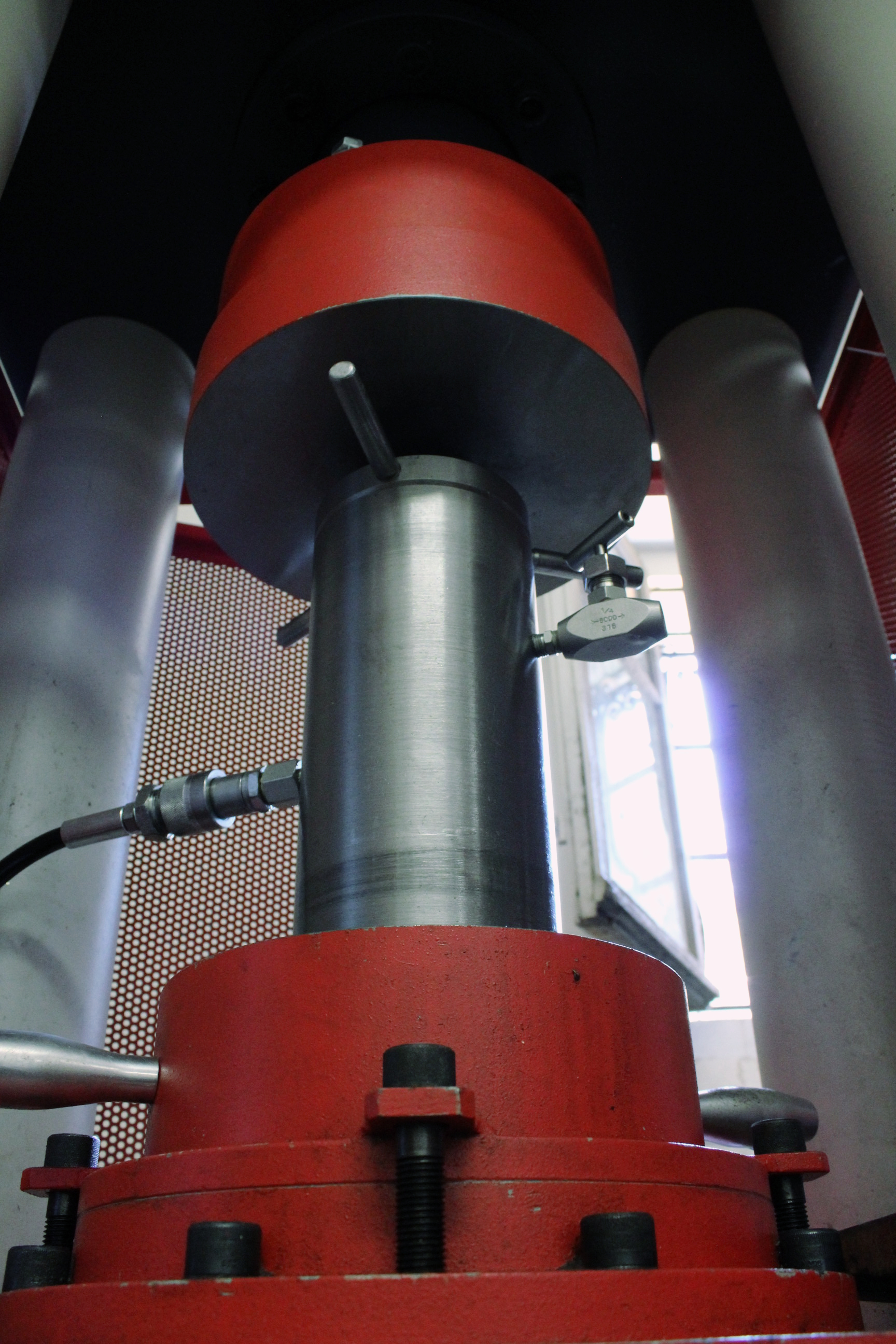

Deformation control compressive test (post-peak behaviour)

What is it?

When subjecting rock to compression, in the stress-strain curve, the post-peak behavior corresponds to the portion from the maximum strength, continuing with plastic deformation until reaching residual strength.

The behavior will depend on the quality of the rock, the formation process, and the discontinuities present in it. In addition to the confining pressure applied to the specimen or rock mass, the size of the specimen and the testing speed at which the test is conducted will also have an impact on the behavior.

What is it for?

The study of progressive failure in rock masses becomes more relevant by incorporating the post-peak behavior as a variable in the constitutive laws applied in numerical models, allowing for a more accurate estimation of plastic deformations of the rock mass. Some fields of application when defining models that incorporate this behavior are:

- Design and stability analysis of underground excavations in mining and civil engineering projects.

- Evaluation of the behavior of foundations of dams, tunnels, and bridges.

- Analysis of slope stability and landslides in geotechnical engineering.

- Assessment of the behavior of rock masses during seismic events and explosions.

- Modeling of hydraulic fracturing in geothermal and oil reservoirs.

- Evaluation of the performance of rock bolts and other support systems in underground mines and tunnels.

- Analysis of the behavior of rock masses in geomechanical and geotechnical studies.

Standard ISRM (1999)

Non-destructive test

Unit weight (bulk density)

Porosity

Pulse velocity (Vp and Vs) with dynamic elastic constants

Petrographic analysis

Scale pictures